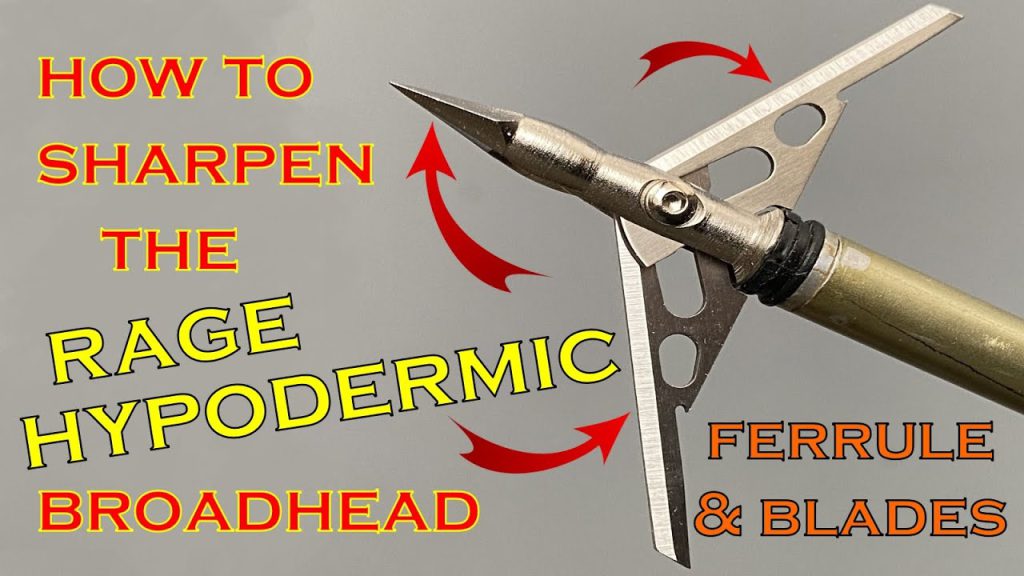

How To Sharpen Mechanical Broadheads

If you’re an archery enthusiast, you know that a sharp broadhead is essential for a precise and effective shot. But when it comes to sharpening mechanical broadheads, it’s a different ball game. Mechanical broadheads are known for their innovative design and cutting-edge technology, which can make sharpening a bit more challenging. In this article, we’ll explore the ins and outs of sharpening mechanical broadheads, including the tools you’ll need, the techniques to use, and some tips to ensure a razor-sharp edge. So, grab your broadheads and let’s dive into the world of sharpening!

Why Sharpen Mechanical Broadheads?

When it comes to hunting with a bow, sharp mechanical broadheads are essential for maximum effectiveness. A broadhead is the tip of an arrow that is specifically designed to cause a significant amount of damage upon impact. It is crucial to keep your mechanical broadheads sharp to ensure a clean and quick kill.

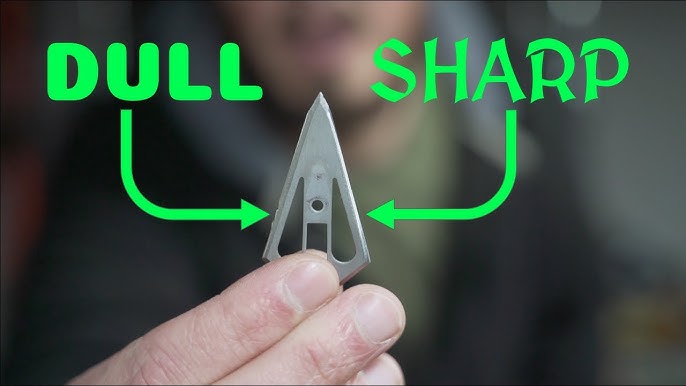

Importance of sharp mechanical broadheads

Sharpness directly affects the cutting ability of a broadhead. A dull broadhead not only reduces the chances of a clean kill but can also cause unnecessary suffering for the animal. A properly sharpened mechanical broadhead can seamlessly pierce through the animal’s hide and vital organs, resulting in a humane and ethical kill.

Benefits of using sharp broadheads

Using sharp broadheads offers several benefits for bowhunters. Firstly, sharp broadheads provide higher penetration, allowing for a better chance of hitting vital organs and leading to a quicker kill. Secondly, sharp broadheads create larger entry and exit wounds, which increases the chances of leaving a blood trail and making it easier to track down the animal. Lastly, sharp broadheads minimize the risk of deflection, ensuring that the arrow travels its intended path and hits the target accurately.

Different Types of Mechanical Broadheads

There are several types of mechanical broadheads available on the market, each with its own unique characteristics and benefits. It’s essential to understand the different types to determine which one suits your specific needs.

Fixed Blade Mechanical Broadheads

Fixed blade mechanical broadheads, as the name suggests, have blades that remain fixed and are always exposed. These broadheads have a reputation for exceptional accuracy and reliability. They are ideal for hunters who prioritize durability and simplicity over mechanical components.

Expandable Mechanical Broadheads

Expandable mechanical broadheads, also known as mechanical or blade-over-body broadheads, have blades that remain folded during flight and expand upon contact with the target. This expansion increases the cutting diameter of the broadhead, resulting in larger wound channels. Expandable broadheads are known for their tremendous penetration and are popular among bowhunters who prioritize large entry and exit wounds.

Hybrid Mechanical Broadheads

Hybrid mechanical broadheads combine the best of both fixed blade and expandable broadheads. They feature retractable blades that fold into the body during flight, reducing drag and providing excellent accuracy. Upon impact, the blades expand to deliver a larger cutting diameter, maximizing damage. Hybrid broadheads offer a balance between accuracy, penetration, and wound size.

Tools and Materials Needed

To sharpen your mechanical broadheads effectively, you will need the following tools and materials:

Sharpening Stone

A sharpening stone is a crucial tool for maintaining the sharpness of your broadheads. Choose a sharpening stone with a fine grit to ensure a smooth and precise sharpening process. It is recommended to use a dedicated sharpening stone for broadheads to avoid contamination from other types of blades.

Honing Guide

A honing guide is an optional but highly beneficial tool to have when sharpening your broadheads. It helps maintain a consistent angle while sharpening and ensures an even and symmetrical edge on each blade. A honing guide can be particularly useful for beginner archers who are still developing their sharpening skills.

Safety Equipment

Safety should always be a priority when working with sharp objects. While sharpening your broadheads, it is essential to wear protective gloves to prevent any accidental cuts or injuries. Additionally, safety glasses should be worn to protect your eyes from any small metal particles that may be released during the sharpening process.

Steps to Sharpen Mechanical Broadheads

Now that you have gathered the necessary tools and materials, let’s dive into the step-by-step process of sharpening your mechanical broadheads:

Step 1: Secure the Broadhead

Before you start sharpening, ensure that the broadhead is securely mounted in a broadhead vise or a mechanical broadhead sharpener. This will prevent any accidental injuries and allow you to have a stable grip on the broadhead while sharpening.

Step 2: Use the Sharpening Stone

Hold the sharpening stone at a consistent angle against the beveled edge of the broadhead blade. Using a smooth and steady motion, move the broadhead across the sharpening stone in one direction. Repeat this process several times, gradually applying more pressure to remove any nicks or burrs from the blade.

Step 3: Maintain the Correct Angle

Maintaining a consistent angle is crucial for achieving a sharp edge on your broadhead. You can use a honing guide to assist you in maintaining the correct angle while sharpening. If you do not have a honing guide, practice sharpening with caution and pay close attention to the angle of your strokes.

Step 4: Clean and Test the Broadhead

After sharpening, carefully clean the blade of the broadhead with a soft cloth to remove any metal shavings or residue. Inspect the broadhead under bright light to ensure that all parts are sharp and free of defects. Once cleaned, perform a test cut on a piece of scrap material to ensure that the broadhead is sharpened to your desired level.

Tips for Effective Sharpening

To sharpen your mechanical broadheads effectively and safely, consider the following tips:

Start with an Unblemished Broadhead

Before sharpening, ensure that the broadhead is free from any significant damage or rust. If there are any dents, cracks, or signs of excessive wear, it may be best to replace the broadhead rather than attempting to sharpen it.

Familiarize Yourself with the Broadhead Design

Different mechanical broadheads have varying designs and blade configurations. Take the time to familiarize yourself with the specific design of your broadhead, as this will help you determine the correct sharpening technique and angle.

Take Your Time and Work Slowly

Sharpening requires patience and precision. Rushing through the process can lead to uneven sharpening, improper angles, or even injuries. Take your time and work slowly, ensuring that each blade receives equal attention and care.

Keep Safety in Mind

Always prioritize safety when sharpening your broadheads. Wear protective gloves and safety glasses to minimize the risk of accidents. Additionally, handle the sharpened broadheads with caution to avoid any unintended injuries.

Test the Sharpness

After sharpening, it is essential to test the sharpness of your broadheads. Conduct test cuts on various materials, such as paper or foam, to gauge the level of sharpness achieved. A properly sharpened broadhead should cut through the test material effortlessly and leave clean, precise lines.

Maintaining Sharpness of Broadheads

Sharpening your mechanical broadheads is only half the battle. Proper maintenance is crucial to ensure that they remain sharp and ready for use. Here are some tips to help you maintain the sharpness of your broadheads:

Inspect the Broadheads Regularly

Regularly inspect your broadheads for any signs of wear and tear, such as chipped or bent blades, loose parts, or rust. It is essential to identify any issues early on and address them promptly, either through sharpening or replacing the broadhead.

Store the Broadheads Properly

When not in use, store your broadheads in a dedicated broadhead case or box. This will protect them from damage, moisture, and other elements that could dull the blades or cause corrosion. Storing them separately from your other archery equipment will also minimize the risk of accidental injuries.

Avoid Hitting Hard Surfaces

To maintain sharpness, avoid hitting hard surfaces with your broadheads. Hard impacts can cause the blades to blunt or become misaligned. It is recommended to use a target designed specifically for broadheads or replaceable target inserts that can withstand the force of the arrow without damaging the broadhead.

Common Mistakes to Avoid

While sharpening your mechanical broadheads, be mindful of the following common mistakes to ensure optimal sharpening results:

Using Incorrect Angles

Using the wrong sharpening angle can negatively impact the cutting performance of your broadheads. Each broadhead design has its optimal sharpening angle, so be sure to familiarize yourself with the manufacturer’s recommendations or seek advice from experienced bowhunters.

Over-sharpening or Removing too much Material

Over-sharpening your broadheads by removing excessive material from the blades can weaken their structural integrity. This can lead to blade breakage or reduced performance. Exercise caution and remove only the minimal amount of material necessary to achieve a sharp edge.

Skipping the Cleaning Step

Cleaning your broadheads after sharpening is an essential step that should never be skipped. Failure to remove metal shavings or residue from the blade can impact the sharpness and overall performance of the broadhead. Take the time to clean the broadhead thoroughly before testing or storing it.

When to Replace Broadheads

Despite proper sharpening and maintenance, there will come a time when your mechanical broadheads need to be replaced. Here are some signs that indicate it’s time to invest in new broadheads:

Signs of Significant Wear and Tear

If your broadheads show signs of significant wear and tear, such as bent or chipped blades, it may be difficult or impossible to restore them to their original sharpness. In such cases, it is best to retire those broadheads and invest in new ones.

Dull Blades and Reduced Penetration

If you notice that your broadheads are no longer cutting cleanly through your test materials or that your arrows are not penetrating as deeply as before, it may be an indication that the blades have dulled over time. Sharpening may provide a temporary fix, but if the problem persists, it’s time to consider replacing the broadheads.

Loss of Accuracy

Mechanical broadheads that have become inaccurate and consistently fail to hit the target accurately may need to be replaced. Factors like bent blades or blade misalignment can significantly impact accuracy, thereby compromising your hunting or archery experience.

Conclusion and Final Tips

The importance of sharpening your mechanical broadheads cannot be overstated. Not only does it ensure a humane and ethical kill, but it also enhances the overall effectiveness and accuracy of your hunts. Regular maintenance and sharpening are key to maintaining the optimal performance of your broadheads.

Remember to always prioritize safety when sharpening your broadheads and use the appropriate tools and protective equipment. Take your time, follow each step carefully, and test the sharpness of your broadheads before heading out to hunt. By maintaining sharp broadheads, you can maximize your chances of a successful and ethical hunting experience.