If you’re new to archery, figuring out What Holds Broadhead Arrow Tips? Simple Answer can feel tricky. Don’t worry, everyone starts somewhere! Many beginners wonder how those sharp tips stay attached to the arrows. This post is all about providing you with clear, easy-to-follow explanations. We’ll break down everything step-by-step so you can confidently set up your arrows. Next up, we’ll get to the main points.

Bonding Arrowheads to Arrows

Attaching a broadhead to an arrow shaft seems simple, but getting it right is vital for accuracy and safety. The connection has to withstand the force of the bow, and impact with a target, or an animal. The connection depends on the type of broadhead, and the materials used for both the arrow shaft and the broadhead. There are several methods for bonding or mechanically securing the broadhead to the arrow. Let’s explore these methods, beginning with the most common.

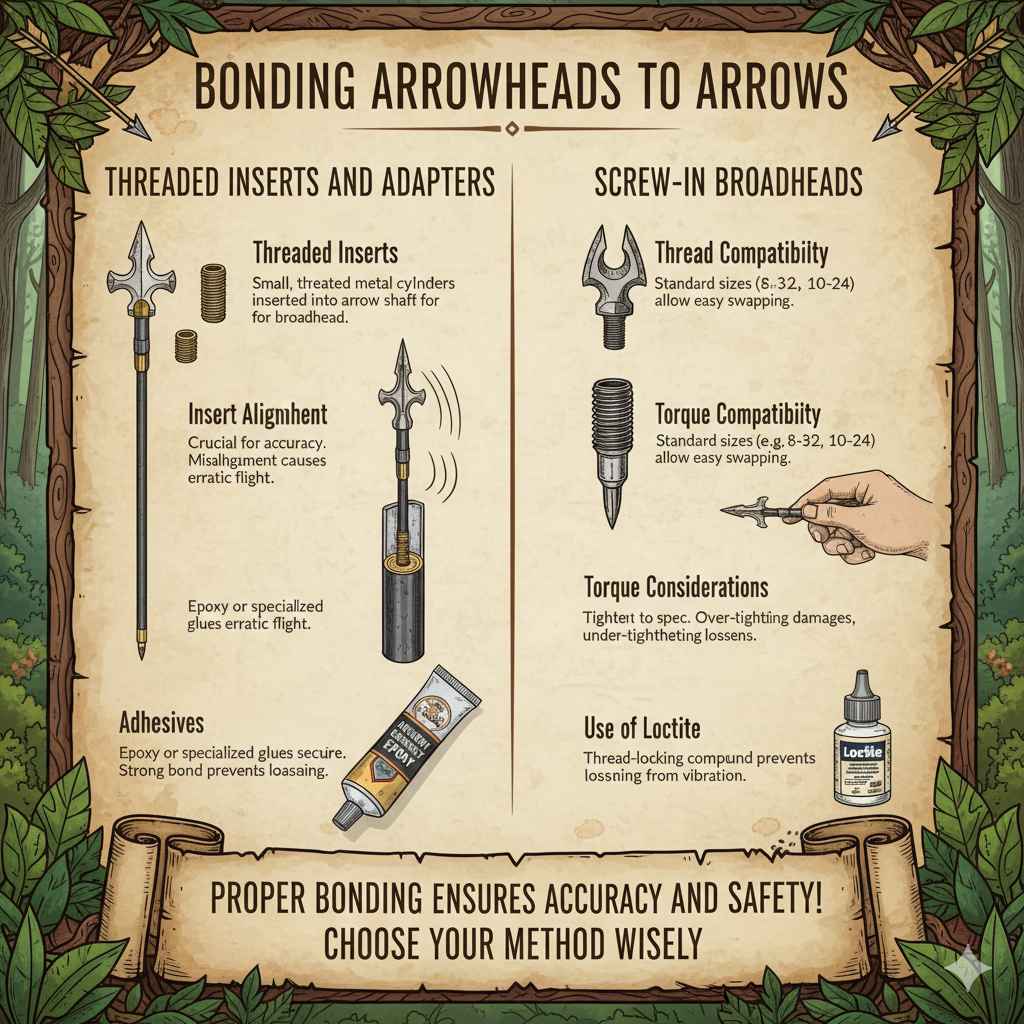

Threaded Inserts and Adapters

One common method for securing broadheads involves threaded inserts. These are small, threaded metal cylinders that are inserted into the arrow shaft. The broadhead then screws onto the insert, creating a secure connection. This method offers several advantages, like the possibility of changing the type of broadhead quickly. The insert also helps to balance the arrow, improving flight. However, it requires careful installation to make sure the insert is aligned correctly, which can be challenging at first. The use of an arrow squaring device, or a shaft spinner is often recommended to make sure that the arrow shaft is perpendicular to the insert. If the insert isn’t aligned correctly, the arrow can fly erratically.

- Threaded Inserts: Threaded inserts are small, usually brass or aluminum, cylinders that go inside the arrow shaft. They have threads on the inside, which the broadhead screws into.

- Insert Alignment: A key aspect of using threaded inserts is ensuring they are straight, or aligned, with the arrow shaft. Any misalignment will affect the arrow’s flight, as the broadhead won’t be centered.

- Adhesives: Many archers use adhesives, such as epoxy or specialized arrow glues, to hold the inserts in the arrow shaft. These glues provide additional security against the insert coming loose during the shot or after impact.

The correct adhesive selection is extremely important. Epoxy is a type of adhesive made of two components: a resin and a hardener. When the two are mixed, they create a strong bond that’s often very durable. It’s useful for gluing things together, or for bonding arrow inserts. Cyanoacrylate glue, commonly known as super glue, also works, but the bond isn’t as strong. Epoxy glues are available in different forms, with varying set times. This allows an archer to choose the adhesive that works best for them. The amount of adhesive, and the time the arrow insert is allowed to dry are also important.

Screw-In Broadheads

Screw-in broadheads are the most prevalent type. The design typically involves threads on the broadhead that directly screw into a threaded insert placed within the arrow shaft. This setup is convenient because it allows for easy installation and removal, which is advantageous for those who regularly practice or change broadheads. The broadhead threads are designed to fit the standard size of the arrow insert threads. Screw-in broadheads are easy to assemble and disassemble, which allows for different broadheads to be used, depending on the shooting task or game pursued. However, it’s important to make sure the broadhead is tightened properly. If it is not tightened enough, it could come loose during flight. The quality of the insert in the arrow is also important, as the threads need to provide a good connection.

- Thread Compatibility: Screw-in broadheads and inserts are often standardized with a common thread size, such as 8-32 or 10-24. This compatibility makes it easier to find replacement parts or swap out broadheads.

- Torque Considerations: Archers usually tighten screw-in broadheads to a certain torque specification, specified by the manufacturer. Over-tightening can damage the insert or shaft. Under-tightening can lead to the broadhead coming loose.

- Use of Locktite: Some archers use thread-locking compounds, such as Loctite, to prevent screw-in broadheads from coming loose. These compounds fill the space between the threads, creating friction that keeps the broadhead securely attached.

The torque, or twisting force, applied to the broadhead when attaching it to the arrow shaft is key to a secure connection. Excessive torque can damage the threaded insert or the arrow shaft, potentially leading to failure. Insufficient torque might allow the broadhead to loosen during the shot or upon impact. It’s usually measured using a torque wrench. Proper torque ensures the broadhead is firmly secured without causing damage. The type of material the arrow shaft is made of can also affect how much torque the arrow can withstand.

Arrow Shaft Materials and Broadhead Compatibility

The material of the arrow shaft plays an essential role in broadhead attachment. Different materials have different strengths, stiffnesses, and ways that they can be used with adhesive or inserts. Some materials lend themselves better to specific attachment methods than others. The size and type of the broadhead also play a role in the selection of the arrow shaft. Arrow shafts are made from a variety of materials, including wood, aluminum, carbon fiber, and fiberglass, and each has unique properties.

Carbon Fiber Shafts

Carbon fiber arrow shafts are popular for their strength-to-weight ratio. They are both strong and light, offering better performance for archers. These shafts can withstand a lot of force, including the impact of a broadhead during a shot. Carbon fiber shafts usually utilize threaded inserts, allowing for easy attachment of screw-in broadheads. Adhesives like epoxy are often used to ensure the insert is securely bonded within the carbon fiber. These inserts are carefully placed to make sure they are aligned, improving arrow flight. Carbon shafts have become a common choice due to their consistent performance. They’re a good choice for both target practice and hunting.

- Durability: Carbon fiber shafts are durable, and resist breaking on impact. This makes them a reliable option for repeated use, even with the high forces involved in archery.

- Insert Compatibility: Most carbon fiber shafts are designed to accommodate threaded inserts. This makes them versatile in allowing different broadheads to be screwed onto the shaft.

- Weight Considerations: Archers often consider the overall weight of the arrow. Carbon fiber shafts can be fine-tuned to achieve the desired weight for optimal flight characteristics. Heavier arrows can penetrate better, while lighter arrows usually fly faster.

When selecting a carbon fiber arrow shaft, the archer will usually consider factors such as the spine of the arrow. The spine refers to the stiffness of the arrow. The spine is carefully chosen to match the bow’s draw weight and the archer’s shooting style. This match ensures that the arrow flexes correctly upon release, which helps to improve accuracy. Another key factor is the straightness of the shaft. Straightness is important for consistent arrow flight. This is often measured using a straightness tolerance, such as 0.001 inches per inch. Archers typically test new arrows with a shaft spinner, to make sure there are no defects.

Aluminum Shafts

Aluminum arrow shafts were very common. Aluminum arrows are known for their consistent performance. They were one of the first types of arrows that could be made with consistent tolerances. These shafts are durable, and work well with screw-in broadheads and threaded inserts. Aluminum shafts are relatively easy to cut to the correct length. They are usually compatible with a wide range of broadhead designs, providing versatility for different shooting scenarios. Although aluminum shafts are less common than in the past, they’re still used by archers, and work effectively with various broadhead designs.

- Strength and Durability: Aluminum shafts are strong enough to withstand the forces involved in shooting arrows, including the impact of a broadhead. This durability provides reliability over repeated use.

- Insert Compatibility: Aluminum shafts readily accept threaded inserts, and are designed for screw-in broadheads. This makes them easy to use.

- Straightness and Consistency: Aluminum shafts are made with precise straightness specifications. This helps archers with accurate shooting.

One downside of aluminum shafts is that they are more prone to bending than other materials, such as carbon fiber. Bends can affect the flight of an arrow. These bends are common if an arrow hits a hard surface, like a rock or a tree. Aluminum shafts are also heavier than carbon fiber, which means that the arrow will travel slower. Despite these factors, aluminum shafts are still a dependable choice for many archers. They are especially effective for archers on a budget, or those who want an easy-to-use, and readily available arrow shaft.

Hybrid Shafts

Hybrid arrow shafts combine different materials. For example, some may combine carbon fiber with aluminum. This can deliver a blend of the strengths of both materials. These hybrid shafts aim to improve durability, reduce weight, or improve spine consistency. The design of hybrid shafts will usually incorporate threaded inserts. This permits the use of screw-in broadheads. The different components of the shaft, such as the carbon fiber, or aluminum layers, usually interact to enhance performance. These shafts seek to minimize drawbacks associated with any single material.

By doing so, they provide a combination of strength, accuracy, and lightweight characteristics. This makes them a good option for archers who want the benefits of both carbon fiber and aluminum arrows.

- Layered Construction: Hybrid shafts use different layers of materials to achieve desired properties. For instance, a carbon fiber layer might be added to an aluminum core for increased strength and reduced vibration.

- Weight Distribution: The combination of materials allows for control over the arrow’s weight distribution. A heavier front-of-center (FOC) balance can improve the arrow’s stability in flight.

- Spine Consistency: Hybrid shafts often have improved spine consistency compared to single-material shafts. This can lead to greater accuracy. The spine is also chosen to match the bow and shooting style.

The combination of different materials allows for a customized arrow performance. The archer can usually choose a shaft that suits the bow’s draw weight, the type of shooting, and personal preference. The use of hybrid shafts reflects a growing trend in archery toward more advanced technology to improve performance. The layers may include additional materials to improve vibration dampening, or penetration capability. Because the selection can be overwhelming, archers should research hybrid arrow options carefully before purchasing. They should consider the design, weight, and spine requirements.

Mechanical Broadheads vs. Fixed Blade Broadheads

The type of broadhead also affects how it attaches to the arrow shaft. There are two primary categories: fixed blade and mechanical. Each has distinct ways of attaching to an arrow. The choice between them often depends on personal preference and the specific hunting situation. Each type has its own advantages, and may require different techniques for installing on the arrow.

Fixed Blade Broadheads

Fixed blade broadheads have blades that are permanently attached, or fixed, to the broadhead body. They are designed to stay open. The connection typically uses screw-in or are no moving parts to fail. The blades usually provide immediate cutting. This is very important. Fixed blade broadheads can be used in almost any archery setup, because they are made in standard sizes. The simplicity of their design also means that they tend to be relatively easy to maintain.

This design is also rugged, and the blades can withstand significant impact without breaking. The archer will have to make sure they are very sharp, because they need to be effective immediately.

- Attachment Methods: Fixed blade broadheads use a variety of attachment methods. The most common is the screw-in design, that fits into the threaded inserts of the arrow shaft.

- Blade Design: Fixed blades come in a wide range of designs. The number of blades varies, from two to four or even more. The blade angle and sharpness significantly impact penetration and cutting efficiency.

- Durability: Fixed blades are known for their durability. They are made to withstand impact without breaking. The blades, and the body of the broadhead are designed for maximum impact resistance.

Choosing the right fixed blade broadhead requires careful consideration. Important factors include blade sharpness, size, and the cut diameter. The blade angle, or the angle at which the blade meets the arrow shaft, also influences penetration ability. A steeper blade angle can result in greater penetration, while a more gradual angle may be better for cutting. Archers also consider the material of the blades, which can affect sharpness and edge retention. The body of the broadhead is also made from various materials, such as steel or aluminum. Fixed blade broadheads are a good option for those who are seeking consistent performance and dependability.

Mechanical Broadheads

Mechanical broadheads have blades that remain closed during flight. Upon impact, the blades deploy, opening to provide a large cutting diameter. They are usually attached with the same methods as fixed blade broadheads. The key difference is the mechanism that deploys the blades. This deployment can be triggered on impact or by the force of the arrow hitting the target. Mechanical broadheads are often favored for their large cutting diameters.

This can lead to larger wound channels and faster kills. However, mechanical broadheads have more moving parts, which means that there’s a risk of failure. This can be mitigated by careful selection of broadhead quality, and regular inspection before use. The blade’s opening mechanism also has to be in perfect working order.

- Blade Deployment: Mechanical broadheads have a spring or other mechanism that opens the blades upon impact. There are many different designs. The design can influence how quickly the blades open, and how consistently they deploy.

- Cutting Diameter: Mechanical broadheads are known for their large cutting diameters. This is because the blades open. The cutting diameter determines the width of the wound channel, and can affect the severity of the wound.

- Reliability: The reliability of mechanical broadheads depends on the quality of the mechanism and construction. It is essential to choose broadheads from reputable manufacturers. This can minimize the risk of failure during the shot.

When selecting a mechanical broadhead, archers usually consider the blade material, the cutting diameter, and the deployment mechanism. The blade material influences the sharpness and the edge retention. A larger cutting diameter can provide a larger wound channel. The deployment mechanism has to deploy quickly. Some mechanical broadheads have a “tip” that expands upon impact. This forces the blades to open.

The design also affects penetration and reliability. Some hunters prefer mechanical broadheads because of the large wound channel. Others prefer fixed blades, for the added reliability. Many archers choose different broadheads for different hunting situations.

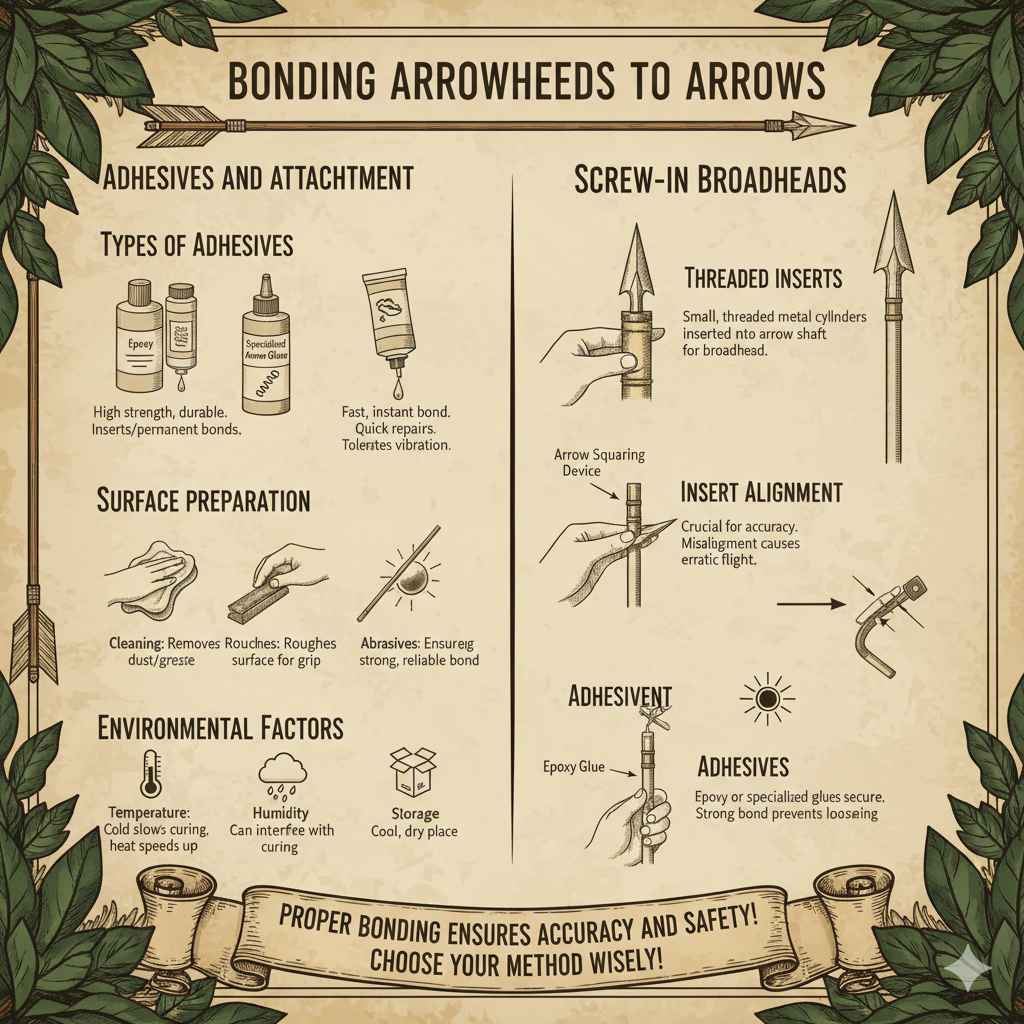

Adhesives and Attachment Considerations

Adhesives are often used in the connection between the broadhead and the arrow shaft. They can increase the security, and longevity of the connection. Choosing the correct adhesive is important for a successful outcome. Correct preparation of the surfaces is also very important. Archers also need to consider environmental conditions. These can influence the performance of the adhesive, or the lifespan of the connection. By paying attention to details, and following the instructions, the archer can make sure the broadhead stays secure.

Types of Adhesives

Several types of adhesives are used in archery. Epoxy, cyanoacrylate, and specialized arrow glues are common. Each type has distinct properties that make it more or less suitable for a specific application. Epoxy glues are known for their high strength. They make a good choice for bonding inserts to the arrow shaft. The epoxy usually comes in two parts that you mix together. Cyanoacrylate glues, also known as super glues, provide a quick, strong bond.

These glues are also useful. Specialized arrow glues are usually formulated to be very flexible. They can tolerate the vibrations and impacts involved in archery. Selecting the right adhesive means understanding each type’s benefits, setting times, and limitations.

- Epoxy: Epoxy glues are known for their high strength and durability. They are commonly used for bonding arrow inserts, and for situations requiring a strong, permanent bond.

- Cyanoacrylate: Cyanoacrylate glues (super glues) offer a fast, instant bond. They can be useful for quick repairs or for securing small parts.

- Specialized Arrow Glues: Some adhesives are specifically formulated for archery. They are often flexible to withstand vibrations and impacts. They can offer both strength and the ability to handle a lot of force.

The choice of adhesive will often depend on the specific task. Some archers prefer epoxy glue for its long-lasting, reliable hold. Others may select cyanoacrylate for the instant bond. Specialized arrow glues are useful when a flexible, high-impact bond is needed. Before using any adhesive, it’s critical to read the manufacturer’s instructions. This will provide the best results. The adhesive must be applied properly, and allowed to cure for the recommended time. Many manufacturers have application videos on the internet that show the best method of using their products. This will guarantee a strong and reliable connection.

Surface Preparation

The preparation of the surfaces to be glued is a key step. This preparation improves the bond. This preparation includes cleaning and roughening the surfaces of the arrow shaft and the broadhead insert. By removing debris and creating a slightly textured surface, you increase the surface area for the adhesive to contact. Use isopropyl alcohol to clean the inside of the arrow shaft and the insert. This removes any grease, oil, or debris that might interfere with the bond. If you’re attaching an insert, you may have to rough up the surface with sandpaper. This will improve the adhesive’s grip. These simple steps enhance the bond’s strength and reliability. They also increase the likelihood of the broadhead staying connected.

- Cleaning: Cleaning removes dust, grease, and other contaminants. This makes sure that the adhesive will contact the intended surfaces.

- Abrasives: Using sandpaper or an abrasive pad roughens the surface. This increases the surface area for the adhesive to bond, and helps the adhesive grip better.

- Dryness: Make sure the surfaces are completely dry before you apply the adhesive. Moisture can weaken the bond and prevent the adhesive from working as designed.

Correct surface preparation provides for a strong bond. The steps include cleaning with isopropyl alcohol. The archer must use sandpaper, or an abrasive pad to roughen surfaces for better adhesion. These processes remove any dirt, oil, or imperfections that might interfere with the adhesive. Cleaning is a vital step. Roughening the surfaces is especially important. This preparation will create a reliable connection. By taking the time to prepare the surfaces, you will increase the probability of a perfect shot.

Environmental Factors

Environmental factors, such as temperature, and humidity, can affect how adhesives perform. Cold temperatures slow down the curing process. High humidity can interfere with the bond. Archers should consider the conditions when attaching their broadheads. Extreme temperatures or humidity might require special adhesives, or extra curing time. The ideal temperature for the adhesive may also be listed in the instructions. It’s also important to store adhesives in a place where they are not exposed to extremes. These considerations are especially important if you are bowhunting in a place with rapidly changing weather.

- Temperature: Cold temperatures can slow the curing time. High temperatures can speed up the curing time, which can lead to a weaker bond if not handled carefully.

- Humidity: High humidity can interfere with the curing process of some adhesives. This is usually more of an issue with some types of adhesives.

- Storage: Store adhesives in a cool, dry place away from direct sunlight, or extreme temperatures. This preserves the adhesive and helps ensure its effectiveness.

Understanding how environmental factors affect the adhesive is very important for a reliable broadhead connection. Archers who are shooting in extreme conditions may need to choose a specialty adhesive. They will also need to carefully prepare the surfaces. The weather conditions will also affect how long the adhesive will need to dry, or cure. Regular inspection of the broadhead connection will catch any issues early on. This will help make sure that the arrow and broadhead will perform reliably. By adjusting techniques and choosing the correct materials, the archer can make sure that environmental conditions will not affect the bond.

Frequently Asked Questions

Question: What is the most common way to attach a broadhead?

Answer: The most common way is to screw a broadhead into a threaded insert in the arrow shaft.

Question: What’s the main function of a threaded insert?

Answer: Threaded inserts are small cylinders that screw into the arrow shaft and provide threads for the broadhead to attach to.

Question: What is the difference between fixed blade and mechanical broadheads?

Answer: Fixed blade broadheads have blades that are fixed in place. Mechanical broadheads have blades that deploy upon impact.

Question: How important is it to clean the arrow shaft and insert before using glue?

Answer: Very important! Cleaning removes debris and contaminants, helping the glue bond better.

Question: What materials are arrow shafts made from?

Answer: Arrow shafts are usually made from carbon fiber, aluminum, or a combination of both (hybrid).

Final Thoughts

So, What Holds Broadhead Arrow Tips? Simple Answer: It depends on the type of broadhead and the arrow shaft. Threaded inserts are most common, with the broadhead screwing directly into these. Adhesives like epoxy provide an extra layer of security, especially when you are using inserts. You can also use fixed blade broadheads, which are robust and reliable. Mechanical broadheads have blades that deploy upon impact, offering a larger cutting area.

Remember to properly prepare surfaces, and consider environmental factors like temperature and humidity. Now that you’ve explored these essentials, you’re better prepared to create a secure, reliable connection between your broadheads and arrows. Go ahead and start practicing, and enjoy the sport of archery!